The vibratory finishing machines for parts with delicate surfaces from metal, plastic, wood and other are intended for rounding edges, removing shutters, degreasing, cleaning, matting, grinding, polishing and after other primary machining, such as plasma, laser and band cutting, milling, turning, grinding and more.

The basic principle: the workpiece is brought into contact with an abrasive material (chips) and an aqueous additive (compound), which leads to a gentle abrasion. Suitable supplies - abrasive chips, compounds, additives, drying agents, polishing pastes, powder additives, liquid additives, anti-corrosion agents.

|

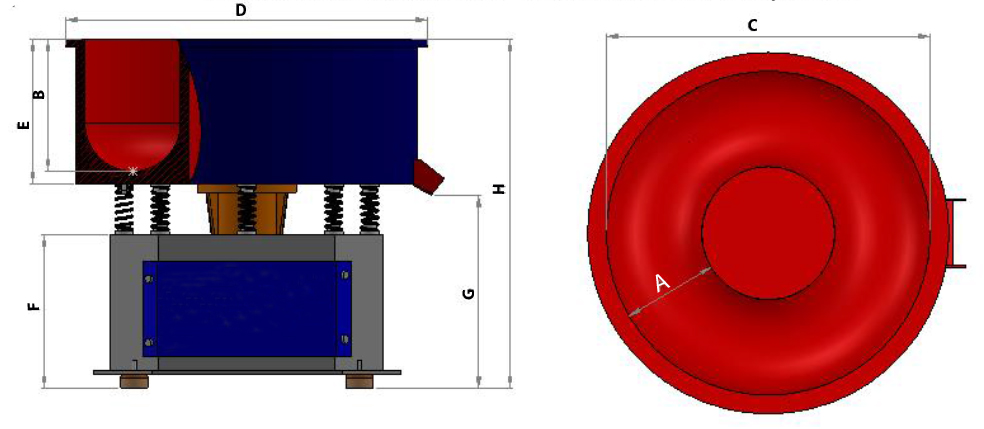

Model |

A

mm |

B

mm |

C

mm |

D

mm |

E

mm |

F

mm |

G

mm |

H

mm |

Motor power

kW |

Engine speed

rp m |

Weight

kg |

|

ZCV 20 |

120 |

200 |

430 |

500 |

240 |

320 |

270 |

580 |

0.17 |

1500 |

80 |

|

ZCV 35 |

140 |

240 |

500 |

580 |

270 |

400 |

350 |

680 |

0.35 |

1500 |

110 |

|

ZCV 75 |

200 |

270 |

670 |

740 |

300 |

500 |

400 |

850 |

0.6 |

1500 |

140 |

|

ZCV 125 |

250 |

330 |

730 |

820 |

365 |

500 |

500 |

900 |

1.1 |

1500 |

220 |

|

ZCV 250 |

260 |

375 |

950 |

1060 |

415 |

500 |

500 |

1000 |

1.1 |

1500 |

350 |

|

ZCV 450 |

360 |

480 |

1200 |

1310 |

520 |

450 |

500 |

1100 |

1.9 |

1500 |

580 |

|

ZCV 600 |

400 |

540 |

1400 |

1520 |

520 |

560 |

500 |

1100 |

2.5 |

1500 |

800 |

|

ZCV 850 |

460 |

590 |

1560 |

1680 |

520 |

620 |

450 |

1250 |

5.0 |

1500 |

1050 |

|

ZCV 1000 |

490 |

650 |

1640 |

1760 |

520 |

680 |

450 |

1250 |

7.0 |

1500 |

1200 |

|

ZCV 1250 |

550 |

670 |

1780 |

1900 |

520 |

700 |

450 |

1270 |

7.0 |

1500 |

130 |