Patented Opal Waterjet Combo is able to combine the advantages of quick plasma cutting with precision of waterjet.

Synergistic effect of combining two different technologies allows the cutting machine to exploit both assets. The cutting machine offers versatility and flexibility for a wide range of users form small to big companies.

Main Features

- Versatility.

- Ully automated cutting process with two different cutting technologies.

- High productivity plasma cutting.

- Dross free waterjet cutting minimizes post processing.

- Reduction of production costs even by 70% with comparison to standard waterjet machines.

- Customized high pressure pump and plasma sources adjustment.

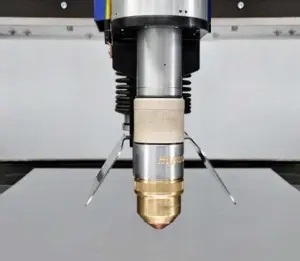

2-axis waterjet cutting head Accustream is utilizing proven in practice hydro-abrasive cutting technology. Well-designed construction head equipped with height sensor and anti-collision device guarantee the best quality cuts and faultless operation.

5-axis Pro-X 3D cutting head provides a very high level of efficiency and insures the achievement of maximum 3-dimensional precision. The maximum cutting angle +/- 60° and automatic angle compensation ensure great precision and practically zero angle on the cutting edge. Perfect tool to minimize post processing.

Water Table - Opal Waterjet cutting machine is equipped with the robust water table with double grid system. Steel, fully tinned (as option) construction insures durability and corrosion resistance. The detached table construction ensures maximum stability and smooth running operations.

ECS872 Control Panel - The most modern i-Vision Controller is the high quality industry machine has Corning® Gorilla® Glass's touchscreen. Efficient parts and the strong construction ensure reliability Onyx working. Many functions of own software and simple controller’s interface let to use all of machine’s possibilities. Standalone controller delivers the unique comfort and safety of machines operator. It make also possible to watching the cutting process and controller’s using at the same moment.

Construction - Opal Waterjet has gantry construction. The machine is made from steel closed profiles which ensure great stability. Rail elements where protected against harmful influence of water with protective bellows or covered by aluminum parts. Relatively low weight of the gantry and specially grounded racks furnishes our Opal Waterjet with excellent dynamics and high precision motors boosts accurate positioning.

HD3000 plasma torch station enables to use all plasma system fully, with all possible features and special technologies. Application of the ball screw gear and high torque servomotor is the unique drive and support leading in Z axes resolution, which allows for more dynamic and increased accuracy in the torch control. This guarantees the perfect distance between the cutting head and the material for maximum cutting quality. Support HD3000 is equipped with sensors: anti-collision, electrical/mechanical touch and height sensor. This allows using technologies such as: Contour Cut®, Contour Cut Speed®, Diameter Pro® and True Hole®.