Main features

- attractive price of richly equipped basic version

- highly dynamic 2D precision cutting of sheets, tubes, pipes and profiles

- capability of processing plates from 0,5 mm to 100 mm thickness

- expanded base of predefined cutting parameters

- unlimited possibility of increasing the length of the working area

- individual customizing options

Jantar is the most chosen model among all the Eckert’s machines, because of its dynamics and cost effectiveness. Jantar is used by several hundred large and small companies in whole Europe that pursuit unsurpassed performance and low working costs.

Jantar cutting machine can be equipped with plasma and oxygen system. Additionally its functionality can be improved by utilizing our wide range of additional equipment - plasma and punch marking, drilling and also tubes, pipes and profiles machining.

Advantages

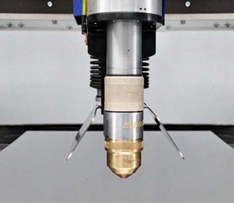

Support HD3000 enables full utilization of the state of the art plasma torches. Application of the ball screw gear and high torque servomotor is the unique drive and support leading in Z axes resolution, which allows for more dynamic and increased accuracy in the torch control. This guarantees the perfect distance between the cutting head and the material for maximum cutting quality. Support HD3000 is equipped with sensors: anti-collision, electrical/mechanical touch and height sensor. This allows using technologies such as: Contour Cut®, Contour Cut Speed®, Diameter Pro® and True Hole®.

Dual Flex2D universal station for oxygen and plasma cutting. The purpose of this solution is to simplify the cutting process with multiple torches at thin or thick materials. It allows both oxygen torch and various available HD plasma sources to work.

Torch change is quick and easy and it takes only a several seconds. While one torch is mounted over the cut metal, the other torch is located in the parking position on the top of the support.

The support has been fitted with anti-collision sensors that prevent any potential collisions of both cutting heads.

Oxygen torch is the cutting solution destined to cut structural low-carbon and low-alloy steel. It is capable of processing wide range of material thickness. The torch was fitted out the height sensor, automatic ignition and possibility of manual angle setting.

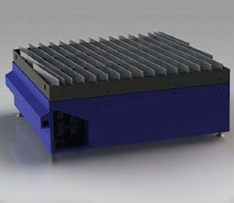

Modular section tables grant efficient elimination of dust during the cutting process. The cutting machine was implemented with the self-supporting construction as the base for the frame with replaceable grids. Such construction offers safe and the best possible safety and performance of the table. The cutting table is provided with intelligent system of dust discharge from the cutting area. Each segment consists of supporting structure with discharge channels, diagonal gird, scrap tank and pneumatic controlled channels.

Control panel ECS872 is a high quality industrial device, equipped with touch screen. Efficient components and construction resistant to extreme production conditions guarantee failure free operation. Unsurpassed functionality of proprietary software and intuitive drive interface enable full exploitation of the machine’s capacity.

Gantry construction is based on welded steel beams which thanks to stress relief is characterised by high rigidity while maintaining relatively small mass. Applied construction solutions assure stability of the machine geometry which is not prone to maladjustment during large mass or thermal loads. This ensures high process safety also for three shift working companies.