- 100% electric drive of all 11 axles.

- Bending head with 360 ° radial axis and horizontal and vertical linear axis.

- Bending clockwise and counterclockwise in an automatic cycle.

- Bending of multiple fixed and variable radii in the same cycle.

- Quick tool change, without having to readjust.

- High working speed and low power consumption.

- Axis movements controlled by servo motors with absolute encoder feedback.

- Simplified synchronization and optimization of bending cycles.

- Compact and ergonomic design for optimal operating comfort and maintenance.

- Sensors that compensate for material bending back and provide greater precision and less waste during the bending cycle.

- Powerful and intuitive VLB 3D software with anti-collision simulation. • Easily program or import files from the cloud or from the network. The cycle speed and low energy consumption make these machines ideal for production with a high volume and high consistency. Because the level of automation is so advanced, they are easy to integrate into automatic production lines or combine with automatic loading and unloading elements. INDUSTRY 4.0 ready machines, thanks to the advanced VLB 3D software.

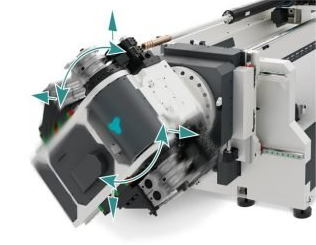

FREEDOM OF MOVEMENT

The EB-RH series tube benders rotative head drive system provides complete freedom of movement. The 360° rotation, combined with the vertical and horizontal axes, allows a quick positioning for the production of very complex bending work. The solution chosen by VLB for the rotation is extremely compact and maintenance-free.

It is structurally robust yet lightweight and with low inertia, allowing for high bending speeds and rapid tool selection adjustments. This unique design dramatically reduces the cycle time of complex bending workpieces.

EASY INTERACTION

The 360º rotation system, together with the vertical and horizontal movements, contributes to the wide range of movement of the bending head. If necessary, deflects the head so that the positioning carriage advances beyond its normal limits.

This feature is particularly important to facilitate integration with automatic loading and unloading systems.